P.I. Engineering, Inc., MI, USA

Manufacturing and Prototype Development Capabilities

History:

P.I. Engineering, Inc. has been designing, manufacturing and distributing human interface electronics since 1993. Those products range from simple USB keypads and mission critical control keyboards, to completely integrated data collection systems and full sized railroad locomotive simulators. The experience that over 30 years of electronic design and production provides allows us to be the perfect partner to bring you ideas and designs to life, here in our Williamston Michigan facility with the help of local and world wide suppliers.

We have successfully brought products of all scale to market, some of our products are produced only a few at a time, but others are made in the thousands per year. We understand the tricks of starting a project, and guiding it from concept to a fully manufacturable product and all the steps along the way.

Our Facilities:

P.I. Engineering owns 2 buildings on over 23,500 sq meters (5.8 acres) of land in the heart of Michigan’s Manufacturing Region. This area has a long history of supporting manufacturing, with its roots going back over 120 years with the first automotive production. Today, Michigan supports a number of high tech and traditional manufactures and is still part of the most active manufacturing region in the United States.

Our business, engineering, shipping, logistics and warehousing facility is a 1000 sq meter building

Our manufacturing, tooling and warehousing facility is a 1,325 sq meter building.

Our Capabilities:

- Complete engineering and design

- PCB layout and procurement.

- PCB assembly, surface mount and through hole.

- Enclosure design and production including:

- CNC metal and plastic cutting lasers and routers

- Hydraulic bending presses, punches, drills, taps and fixture production.

- Stock extrusions and plastic components

- Custom engineering of injection molded plastic parts.

- Coating and decorating of finished parts.

- Final assembly and QC testing.

- Packaging, packing, and complete fulfillment.

Our Equipment:

- Complete Surface Mount Pick and Place line.

- Precision stencil machine for fine pitch SMT

- Lead free wave solder machine.

- Special large component and rework solder equipment.

- Ultra sonic welder and heat staking equipment

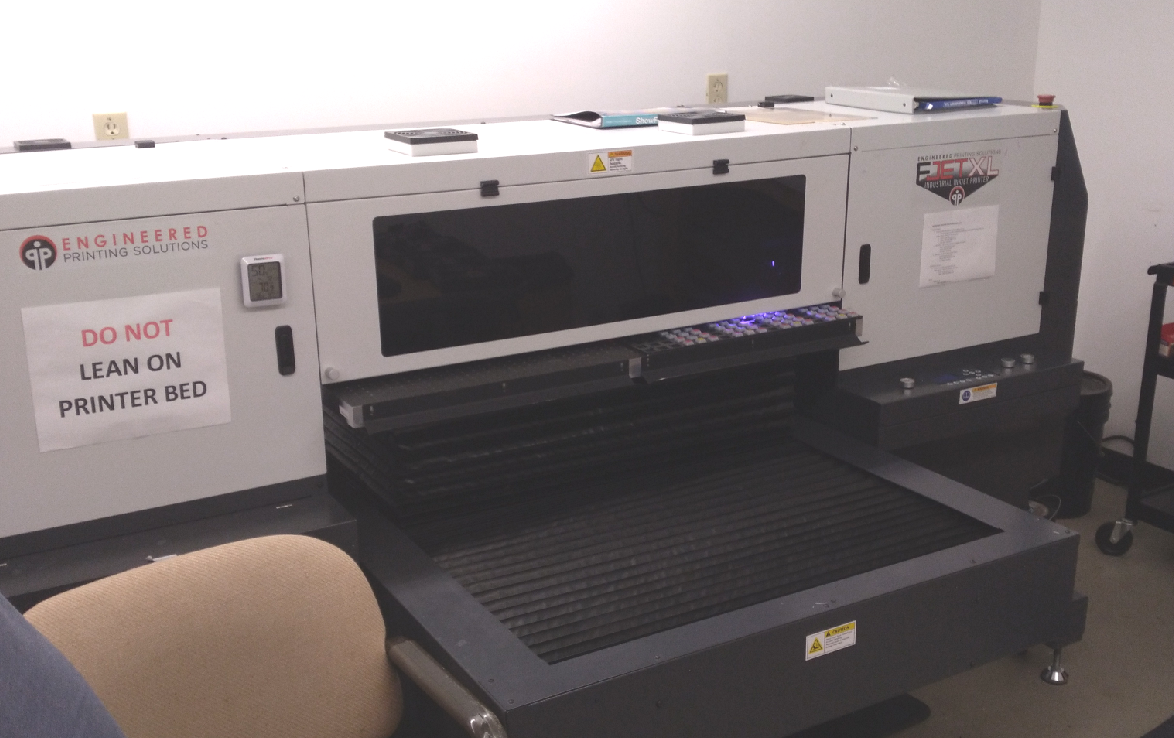

- High Speed large format direct to substrate acrylic printer

- Metal cutting laser

- Plastic and engraving lasers

- Metal fabrication press breaks

- 40 ton punch presses and shears

- CNC Routers

- Steel tooling production shop

- Mig and Tig welding equipment

- Retail and commercial packaging equipment

- Foam packing equipment for heavy products

- Raw material and finished product warehousing

Our staff:

The experienced and dedicated staff at P.I. Engineering Inc. are always be available to manage and guild any project. From start to final fulfillment. And after the sale with RMA and repair facilities in house.

- Knowledgeable local tech support department

- Dedicated Sales and Project management staff

- Experienced Engineering and design staff.

- Shipping and fulfillment department

Our Products:

Products we have manufactured range for small electronic components to industrial pumping and atomization equipment. With the majority being fully finished computer input devices for mission critical applications.

Our Commitment to Quality:

We market, sell and support many of the products we manufacture, so we know the importance high quality and a close to 0% failure rate. Additionally, many of our customers use the products we produce in mission critical applications, with over 30 years of experience; we fully understand the need for superior quality in both the product and the service we provide before and after production.

If any product does fail in our tests or in the field, it will be sent to the engineering department for “root cause failure analysis”. After determining the root cause, any improvement in production, components or design will be implemented to prevent a repeat of the failure. We adopt a continuous quality improvement process.

To ensure consistent high quality we are currently obtaining our ISO 9001 certification for our Williamston, Michigan facility.

Trusted Partnerships:

The importance of long-term trusted partnerships between P.I. Engineering and our suppliers and customers guilds our daily business. During our many years of business we have built many such relationships, but we continue to strive to improve those and create new long-term partners. P.I. Engineering Inc. can help with many manufacturing, support and distribution needs here in our Michigan based facilities.